The impact of electrical harmonic pollution of warp knitting machines in the textile industry on equipment stability

The patented product DN-V voltage quality harmonic eliminator developed by Lite Electric Energy Company for warp knitting machines can not only solve the voltage fluctuation of the warp knitting machine, but also eliminate the problem of electric energy harmonic pollution

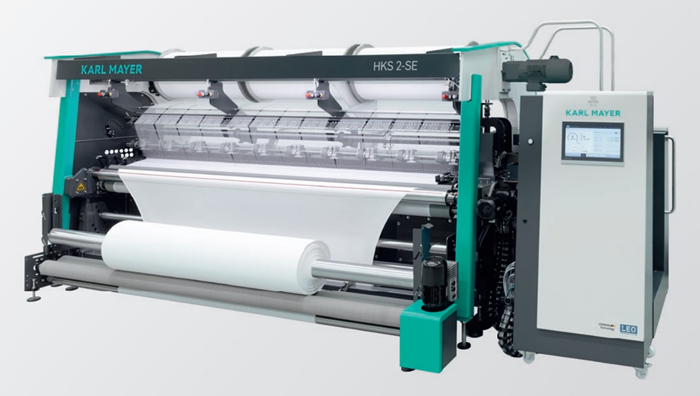

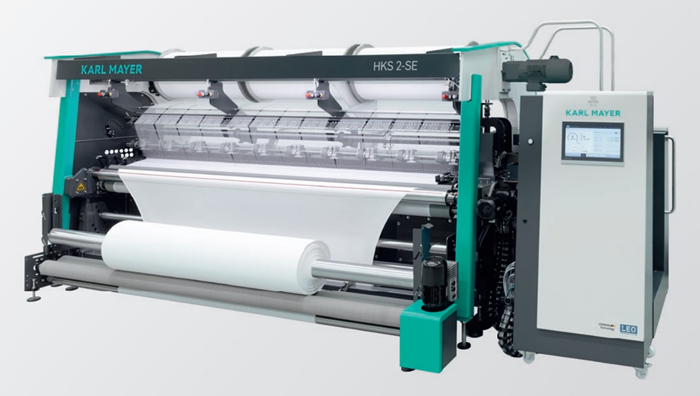

1、 What is a high-speed warp knitting machine

The knitted fabric of a high-speed warp knitting machine is formed by feeding one or several sets of parallel yarns into all the working needles of the machine simultaneously along the warp direction. This method is called warp knitting, and the fabric is called warp knitted fabric. The machine that completes this type of warp knitting is called a high-speed warp knitting machine. The warp knitting machine is mainly composed of a weaving mechanism, a horizontal bar moving mechanism, a warp feeding mechanism, a tension winding mechanism, and a transmission mechanism. The knitting mechanism includes needle beds, rods, sinker beds, and pressure plates, which are generally driven by cam or eccentric links. The cam of high-speed warp knitting machines is commonly used for low-speed and complex motion patterns of loop forming components. Eccentric connecting rods are widely used in high-speed warp knitting machines due to their advantages of smooth transmission, easy processing, low wear during high-speed operation, and low noise.

2、 Structure of warp knitting machine

The warp knitting machine mainly has one main spindle part. 2-link rocker shaft section. 3 parts in a circle. 4 comb bar horizontal movement section. 5. Transmission section of the warp shaft. 6 Pulling and coiling parts. 7-minute yarn tension section. 8 Electrical system section. 9 Other auxiliary configurations. The main components of a warp knitting machine are knitting needles, guide needles, sinkers, and pressure plates (used for crochet machines). The knitting needles are arranged in a row on the needle bed and move with the needle bed. The yarn guide needle is installed on the Flat noodles to form a comb. The warp yarn passes through the holes of the guide needle, moves with the rod and wraps around the guide needle, and is woven into fabric through the coordinated movement of loop components such as knitting needles and sinkers. The warp knitting machine is mainly composed of a frequency converter, servo motor, rectifier module, and electrical control system.

3、 Power supply mode of warp knitting machine

The voltage standard for electricity in China is three-phase four wire power supply, with a line voltage of 380V and allowable deviation; 7%. Many imported or domestically produced warp knitting machine control modules require an input voltage of 380V; 2%.

4、 The harm of electrical harmonic pollution to warp knitting machines

1. Harmonic pollution of electrical energy causes program interference on the control system program of warp knitting machines.

2. Harmonic pollution from electrical energy can cause significant voltage fluctuations in the input voltage of warp knitting machines.

3. Harmonic pollution of electrical energy affects the control unit module of warp knitting machines, PLC,EMC, Drivers and other electronic components generate certain impact effects.

4. The severe harmonic pollution of electrical energy has caused the burning of electrical equipment components such as frequency converters and motors in warp knitting machines.

5、 Harmonic pollution of electrical energy and its impact on warp knitting machine faults

1. Harmonic pollution can cause electromagnetic interference problems, and in severe cases, it can alter the program settings. The serious situation causes the warp knitting machine to produce unqualified products, resulting in waste.

2. The harmonic pollution of electrical energy affects the fluctuation of input voltage, which can cause changes in the speed of the warp knitting machine. The change in voltage directly affects the material quality and normal speed of the control needle knitting.

3. The impact of electric harmonic pollution on control units often leads to some uncommon accidents, such as broken needles, broken wires, broken wires, hooked wires, etc

4. In the case of significant harmonic pollution of electrical energy, it can also cause overcurrent and overvoltage impacts on the electrical main components of the warp knitting machine, which can affect the lifespan and quality of the equipment, or cause equipment failure or burnout damage.

6、 The patented product DNV anti harmonic regulator developed by Lite Electric Energy Company for warp knitting machines can not only solve the voltage fluctuation of the warp knitting machine, but also eliminate the problem of electrical harmonic pollution.

7、 On site Case Study of DNV Harmonic Suppressor Used for Knitting Machines by Lite Electric Energy Company