- Quality Assurance

- Efficient and secure

- Fully Automatic

- maintenance-free

The use of ore blast furnaces generates a large amount of harmonics, resulting in severe harmonic pollution in the power grid. Mineral heat furnaces are generally supplied with DC power by controllable silicon rectifier devices. The thyristor rectifier device will generate significant reactive power and harmonic current on the AC side, resulting in severe distortion of voltage and current waveforms, low power factor, high incoming current, reduced transformer utilization, and increased energy consumption. Harmonics can also interfere with the crystal pulling control system, causing misalignment, crystal breakage, and tripping, seriously affecting normal production. Mineral arc furnace is a high energy consuming electric smelting furnace with the characteristics of a resistance arc furnace. The power factor is determined by the arc and resistance R inside the furnace, as well as the resistance R and reactance X values in the power circuit (including transformers, short grids, collector rings, and electrodes). COS Φ=(R+R)/resistance R reactance X value generally does not change during the operation of the ore blast furnace, and they depend on the design and installation of the short network and electrode arrangement. The resistance R is related to the current density of various current carrying components on the short circuit during operation, and the variation is small. However, the resistance R is the main factor determining the power factor of the submerged arc furnace during operation. Due to the weaker resistance of the ore smelting furnace compared to other electric smelting furnaces, its power factor is correspondingly reduced. Except for the natural power factor of general small mineral heat furnaces that can reach 0.9 or above, the natural power factor of medium and large mineral heat furnaces with a capacity of 10000KVA or above is below 0.9. The larger the capacity of the mineral heat furnace, the lower the power factor. This is because the larger the inductive load of the transformer in a large capacity mineral heat furnace, the longer the short network, and the deeper the electrode insertion into the furnace material, which increases the reactance of the short network and thus reduces the power factor of the mineral heat furnace. In order to reduce power grid losses and improve power supply quality, the power supply bureau requires that the power factor of electricity consuming enterprises must be above 0.9, otherwise they will be fined heavily. At the same time, a low power factor will also reduce the incoming voltage of the ore smelting furnace, affecting the smelting of calcium carbide. Therefore, at present, both domestic and foreign high-capacity submerged arc furnaces need to be equipped with reactive power compensation devices to improve the power factor of the furnaces.

The reactive power compensation devices currently in operation are usually divided into the following two ways based on the access point of the compensation device:

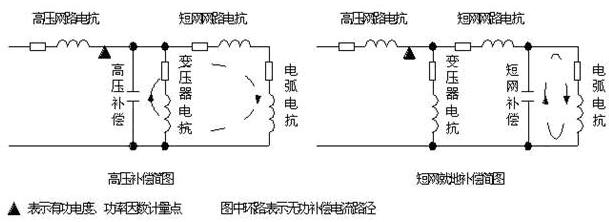

1. The compensation device is connected to the high voltage side of the ore furnace transformer, which is called high voltage compensation;

2. The compensation device is connected to the low voltage side of the ore furnace transformer, which is called low voltage compensation;

2、 Reactive power compensation device

1. High voltage compensation

The high voltage side voltage of the ore furnace transformer is generally 10KV, 35KV, or 110KV. There are two types of high-voltage compensation: one is to directly connect the compensation device to the high-voltage side; Another way is to connect it to the high voltage side through a compensating transformer. Compensation devices with corresponding voltage levels (including power capacitors, switches, reactors, lightning arresters, protection equipment, etc., the same below) can be directly connected to the high voltage side of the submerged arc furnace transformer (the compensation device is connected to the input end of the submerged arc furnace transformer), or directly compensated separately or centrally in the substation. Its characteristics are:

1) Simple equipment and low investment;

2) When the compensation device malfunctions, the current does not pass through the ore furnace transformer;

3) The compensation device is not affected by changes in the wiring of the ore furnace transformer or other aspects of the ore furnace.

2. Low voltage compensation

2.1 Principle

Low voltage compensation is a reactive power compensation device that uses modern control technology and short network technology to connect large capacity and high current ultra-low voltage power capacitors to the secondary side of a submerged arc furnace. This device not only embodies the principle of reactive power compensation, but also enables the power factor of the ore blast furnace to operate at a higher value, reducing the reactive power consumption of the short network and primary side, and eliminating the 3rd, 5th, and 7th harmonics. Leveling the three-phase power and improving the output capacity of the transformer. The focus of control is to reduce the imbalance of three-phase power and achieve equal three-phase power. Expand the crucible, concentrate heat, increase the furnace surface temperature, accelerate the reaction, and achieve the goal of improving product quality, reducing consumption, and increasing production.

This technology belongs to the application of mature on-site compensation technology to the secondary low voltage side of the submerged arc furnace. The reactive power generated by capacitors is absorbed by the system through a short line, partially through the submerged arc furnace transformer, and partially compensates for the reactive power loss of the submerged arc furnace transformer, short network, and electrodes, increasing the active power input to the submerged arc furnace. At the same time, phase separation compensation is adopted to make the active power on the three-phase electrodes in the ore blast furnace equal, achieving the effect of improving power factor, reducing three-phase power imbalance, and improving production indicators. Advantages of using low-voltage on-site compensation/filtering technology:

1. Low voltage compensation can improve the utilization rate of transformers and high current lines, increase the effective input of smelting,

2. Improve three-phase imbalance.

3. Reduce high-order harmonic values.

4. Reducing transformer and network additional losses can eliminate power regulation electricity costs and save energy and reduce consumption.

5. Improve the active power output of the ore smelting furnace transformer, thereby increasing production and economic benefits.

Tel: 0755-29756357 13560785740

Mr. Chen (Hong Kong):852-93799194

E-mail: 13560785740@163.com / chankentac@gmail.com

Address:209, Building E, Zhongzhi Creative Industry Park, No. 4 Tangrun Road, Zhangge Community, Fucheng Street, Longhua District, Shenzhen

地址:深圳市龙华区福城街道章阁社区塘润路4号中志·创意产业园B栋101