- Quality Assurance

- Efficient and secure

- Fully Automatic

- maintenance-free

1. DNAN Intelligent Zero Line Current Processor Technology:

The DNAN zero line current processor equipment is mainly used to solve the problem of excessive zero line current caused by zero sequence harmonics (especially 3rd harmonic) and three-phase unbalanced currents in three-phase four wire distribution systems. Its core principle is to use the DNAN module dynamic filtering reactor composed of zero line current processing technology to eliminate the zero line current on the load side and ensure distribution safety. The following is its detailed working principle:

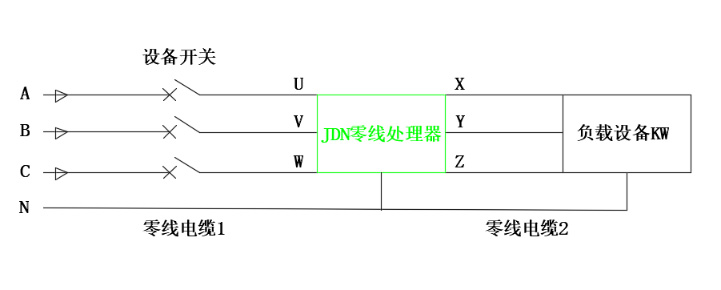

Figure 1 (Installation and wiring diagram of DNAN neutral current processor)

2. DNAN Intelligent Zero Line Current Processor Wiring Method:

The load series connected DNAN zero line current processor equipment uses a series type zero sequence filter to control the harmonic current of the zero sequence harmonic current (3rd harmonic), and then the DNAN module controls and adjusts the magnetic flux of the series type zero sequence filter to automatically eliminate the zero sequence harmonic current (3rd harmonic) in real time. At the same time, it also compensates for the three-phase unbalanced current of the output current, reduces the three-phase unbalanced tripping of the upper level main switch, improves the three-phase current balance of the transformer load, and protects the transformer.

3. The core processing principle of DNAN intelligent adjustment zero line current processor

Technical principle: Zero sequence harmonic cancellation method generates reverse current by real-time monitoring of the harmonic components (mainly the 3rd harmonic) of three-phase current through high-precision CT. The equipment quickly generates compensation current with equal amplitude and opposite phase to the harmonic through IGBT inverter, and injects it into the load system. Governance effect: The total harmonic current of the neutral line is cancelled out and significantly reduced to a safe range (such as from 100A to below 10A).

The principle of using magnetic filters to deal with excessive zero line current: Magnetic filters are mainly composed of magnetic rods/plates (high permeability materials such as ferrite or neodymium iron boron) and fluid channels (designed as multi-layer or spiral channels). The zero line current is mainly composed of 3N harmonic sources of the load stacked on top of the zero line. We need to understand the low impedance and magnetic flux direction of the 3N frequency. The 3N harmonic source generated on the load side will feedback to the grid side, generating magnetic flux in one direction during the feedback process. By monitoring the magnetic flux reversal of 3N harmonic sources. A reverse magnetic flux is generated inside the magnetic filter, causing the 3N harmonic sources to cancel each other out inside the coil. Thus eliminating the feedback of 3N harmonic sources to the grid side and eliminating the zero line current on the grid side and load side.

4. DNAN Intelligent Zero Line Current Processor Processing Method:

The advantage of load series connection in eliminating zero line current is that at the installation point, it can simultaneously eliminate the zero line current from the equipment to the transformer (as shown in Figure 1, the zero line current at the upper end of neutral cable 1 can be eliminated by more than 90%) and also eliminate the zero line current from the equipment to the load side (as shown in Figure 2, the zero line current at the upper end of neutral cable 2 can be eliminated by more than 90%).

5. Advantages of DNAN Intelligent Zero Line Current Processor:

1) The equipment has high efficiency in automatically processing zero line current, and the touch screen on/off (with automatic bypass) operation mode is to connect the load in series with automatic switching bypass, which can compare the zero line current elimination effect before and after input. The fault alarm will automatically switch to the bypass (without manual operation), and a mobile SMS will be sent to notify the equipment management responsible person that there is a fault alarm and someone needs to be sent to check it.

2) Automatically adjust the three-phase unbalanced current of the load, protect the upper level switch from generating unbalanced current tripping, and ensure the safe use of electricity by the load.

3) Automatically eliminate the zero line current generated by the load, eliminate over 90% of the zero line current, eliminate the fire hazard caused by the heating of the zero line cable, and protect the safe and normal operation of the zero line cable.

4) The output terminal voltage of the serial device will not generate voltage difference, and the output phase voltage will be basically balanced without causing the load light to flicker, and will not cause the load controller to generate high voltage or low voltage alarm, ensuring the normal operation of the load.

5) The device is easy to use and automatically starts working after being wired and powered on. Automatically adjust the three-phase unbalanced current of the load and eliminate the zero line current.

6. The difference between DNAN intelligent zero line current processor and traditional zero line current elimination:

| Product Name | Technical Features | Difference between advantages and disadvantages |

| Three phase series zero line current eliminator | At the same time, it can eliminate the current of the zero line wires at the upper and lower ends of the installation point. The zero line current elimination rate reaches 90% in the balanced state of the three-phase load current, and the effect of eliminating the zero line current becomes worse when the three-phase load current is unbalanced. | The effect of eliminating zero line current due to unbalanced three-phase current of the load deteriorates. Connecting the three-phase output voltage in series with a phase voltage of 220V will result in voltage deviation, which affects the normal operation and use of the load. Causing the user's lights to flash, the motor to stop, and protection false alarm. 90% of manufacturers on the market do not have protective functions, but serious accidents occur due to short circuits. (Multiple cases) |

| Three phase four wire parallel filter | Using modular parallel connection to process the 3rd harmonic current on the load side to reduce the zero line current can only eliminate the zero line current from some installation points towards the upper end, but cannot eliminate the zero line current on the lower load side. The zero line current elimination rate reaches 60% in the balanced state of three-phase load current, but the effect of eliminating zero line current becomes worse in the unbalanced state of three-phase load current. | The effect of eliminating zero line current due to unbalanced three-phase load current becomes worse. The parallel installation point can only eliminate the zero line current to the transformer side, but cannot eliminate the zero line current from the installation point to the load, and cannot compensate for the unbalanced three-phase current on the grid side. Unable to comprehensively eliminate zero line current, the three-phase current will increase during use, and the lower zero sequence current will increase instead of decreasing. |

| ★ DNAN Automatic Regulator ★ | The series connected equipment can simultaneously eliminate the current of the zero line wires at the upper and lower ends of the installation point. The zero line current elimination rate reaches 90% when the load three-phase current is balanced, and 90% when the load three-phase current is unbalanced. | The effect of eliminating zero line current due to unbalanced three-phase current of the load remains unchanged. Connecting the three-phase output voltage in series with a phase voltage of 220V will produce a voltage that is neither too high nor too low, while also compensating for the unbalanced three-phase current on the grid side. |

7. DNAN Zero Line Current Processor Technical Data

The technical data listed in this table are common specifications. If you have any special requirements, please contact us.

| environmental conditions |

Environmental temperature -25 ° C to 55 ° C Storage temperature -40 ° C to 65 ° C Maximum relative humidity of 95%, no condensation Installation at an altitude of less than 2000 meters (customization is required for other special requirements) |

| ELECTRICAL CHARACTERISTICS |

Rated voltage (V) AC380 ± 15% Operating frequency (Hz) 50 ± 5% Response time 1ms Active power loss<3%>Overload capacity 120%, 1 minute Mean time between failures ≥ 100000 hours |

| ELECTRICAL WIRING | Three phase three wire series connection |

| insulation class | F level (B level under normal operating conditions) |

| Protection level |

1. IP protection level: IP30 2. Rust (oxidation) protection: The iron casing of the device and the exposed iron brackets and parts should be treated with rust prevention measures to avoid oxidation and rusting. Non iron metal casings should also have an oxidation protection film or undergo oxidation treatment. |

| Reference standards |

GB/T14549-93 "Electric Energy Quality: Harmonics in Public Power Grids" GB/T15543-1995 "Power Quality: Allowable Unbalance of Three phase Voltage" GB/T15945-1995 "Power Quality: Allowable Deviation of Power System Frequency" GB/T12326-2000 "Power Quality: Voltage Fluctuations and Flicker" GB/T12325-2003 "Power Quality: Allowable Deviation of Supply Voltage" GB/T18481-2001 "Power Quality: Temporary Overvoltage and Transient Overvoltage" |

Tel: 0755-29756357 13560785740

Mr. Chen (Hong Kong):852-93799194

E-mail: 13560785740@163.com / chankentac@gmail.com

Address:209, Building E, Zhongzhi Creative Industry Park, No. 4 Tangrun Road, Zhangge Community, Fucheng Street, Longhua District, Shenzhen

地址:深圳市龙华区福城街道章阁社区塘润路4号中志·创意产业园B栋101